| Forest Road Drainage Installation Practices | |

| in the Pacific Northwest | |

| 7 - Other Issues | Deactivation, Water Quality, Piping |

Deactivating drainage structures often involves instream work. Therefore, deactivation measures chosen should reflect the risks to fish habitat and downstream water users. When dealing with fish on site, check the appropriate fisheries windows and apply alternative measures for risk reduction such as constructing a diversion dam. If the removal of the drainage structure extends over several days such as with big fills, avoid long weekends or shutdown periods to minimize the exposure of unfinished projects to the elements. Check the weather forecast to reduce the exposure to long periods of rain. Have a backup plan in place and carry a well stocked sediment control kit on site. Erosion control measures must be maintenance-free due to lack of access. Check the Forest Road Deactivation Infoflip for further details.

Protect water quality in fish streams and streams that are in close proximity to fish habitat. Water quality must also be protected in streams that flow directly into legal domestic or community water supply intakes. In BC, check the Federal Fisheries Act (specifically Sect. 35 and 36), the BC Water Act (specifically Sect. 43), and the Canadian Drinking Water Standards for legal requirements. As a rule of thumb, visually detectable discoloration of water means that the water is unacceptable for domestic consumption. Be prepared for this situation during the installation of drainage structures. Always anticipate the worst, have a contingency plan, be prepared to use the sediment control kit and apply risk reduction measures immediately if a deterioration of the water quality occurs.

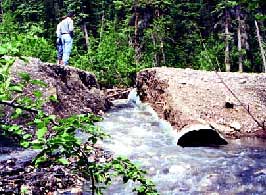

They are caused by a combination of poor bedding materials and the lack of compaction around the culvert. Water is allowed to filter through the road fill material alongside the culvert, and can erode enough fines to cause the collapse of the road fill beside the structure. The practice of placing logs in the fill around pipe culverts may protect the culvert and assist in the recovery of pipes during road deactivation. However, these logs do not allow any fill compaction around pipes and therefore speed up the process of piping. Seepage collars prevent piping. Dual Pipes If one large pipe culvert would create too much of a vertical break in the road alignment, two smaller culverts should be considered as an effective alternative. Compaction is even more critical with dual installations. Ensure that the culverts are placed with at least 1.5 times the width of the excavator bucket apart, to assist in the compaction efforts between the pipes and around the low side (haunches) of the culverts. To ensure fish passage consider placing one pipe at a lower elevation for regular/low flows, and a higher pipe for peak flows.

| 7 - Other Issues |

| Next |

||

|

PLANNING ISSUES

Other Issues 7

|

INSTALLATION PRACTICES |

|

©1999 - 2001 Flip Productions Limited Used with permission by CulvertBC |